The Buzz on Metal Coating Near Anderson, Sc

Table of ContentsNot known Facts About Techline Ceramic Coatings Near Anderson, ScNylon Coatings Near Anderson, Sc Fundamentals ExplainedXylan Coatings Near Anderson, Sc Fundamentals ExplainedThe Of Nylon Coatings Near Anderson, Sc

In return, the steel starts to oxidize and also the atoms liquify and also transform into positive ions. https://en.gravatar.com/vanguardllc. The current after that forces the relocate to the negatively billed substratum, leading to a thin coating of metal. Three aspects might affect just how top quality the metal covering is. First is the bathroom conditions. The temperature of the bath as well as its chemical makeup need to be simply right to make certain the electroplating process is effective.The third variable is how high the electrical current is, as this will have an influence on just how the electroplating process plays out. Improved firmness of the substrate product to help extend their lifespan An affordable technique of enhancing electric conductivity Enhanced appearance for a much more appealing look Safety obstacle against ecological components Steels such as zinc, tin, copper, nickel, gold, silver, and also palladium all utilize the electroplating process.

Sherardizing additionally described as vapor galvanizing or completely dry galvanizing is a procedure that creates a protective layer of zinc-iron alloy on top of steel or iron. It has been exercised because about 1900 as well as it is called after Sherard O. Cowper-Coles, the developer. The object starts by obtaining heated up in a closed container with very high temperature levels before it goes right into a revolving drum.

What Does Nylon Coatings Near Anderson, Sc Do?

Examples of objects that frequently undertake sherardizing include rail track fittings, different cable hooks, steel bolts, universal joints, or rubber bonding. The adherent surface area that arises from the sherardizing process is ideal for: Painting Metal-to-rubber bonding Lubricating substances Organic finish applications Oils Sealants Different types of finishes are all made use of in specific circumstances (Teflon coating in Anderson, SC).

It's possible to dip steel parts right into thermoplastic powders to develop a safety layer - Powder coating in Anderson, SC. It is also described as fluidized bed dipping and also it is just one of the earliest types of plastic finishes that exists, dating back to 1952. There is a polycarbonate finish that's ground right into a great powder and also stored in a fluid bed in addition to a layer of great gauze.

Next, air moves with the gauze to enable the bits to increase and move as liquid would. To prepare the steel element for a plastic coating, it needs to be degreased as well as fired blown up. It can after that be warmed between 250-400 degrees Celsius while the exact temperature hinges on the kind of finishing that's required. https://vanguardmetalcoatingllc05936.collectblogs.com/60385121/excitement-about-vanguard-metal-coating-llc.

The result is a smooth, also plastic layer. The number of layers required is also lowering thanks to this boost in paint high quality and performance.

Getting The Nylon Coatings Near Anderson, Sc To Work

As long as the appropriate protocols are followed, the right prep work is completed, and also the problems are optimal, the paint covering on metal structures must have the ability to endure also the most severe climate problems. Steel coatings can be put on a variety of elements to decrease the threat of corrosion and help the material last longer.

The metal is immersed in the zinc to create a protective covering. Hot-dipped aluminum-silicon can stand up to warm up to 1250 degrees Fahrenheit and it has a warmth reflectivity of 900 levels Fahrenheit, meaning light weight aluminum finishes are suitable for coating warm panels, shields, vehicles, and much more.

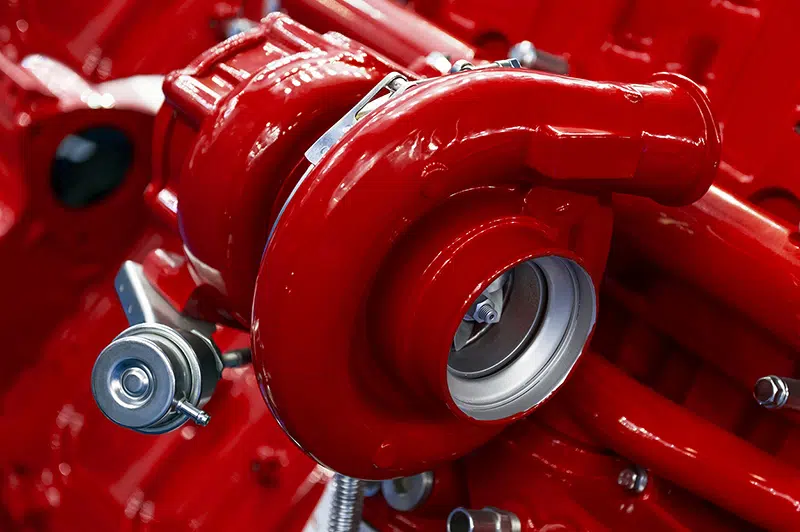

This kind of metal coating is suitable for applications in the clinical area, automotive industry, aerospace industry, and much more. Ion plating is suitable for layers that fit unique as well as intricate surface areas.

What Does Teflon Coating Near Anderson, Sc Mean?

Some highlights of metal coatings include: Reduce rubbing between 2 things rubbing with each other, Protection from possibly damaging chemicals, Protection against corrosion, oxidation, and also deterioration, Assists simplicity assembly as well as disassembly processes, Non-stick attributes make the cleanup procedure easy as well as straightforward, Rises the durability in items, Improves the look of products by getting rid of defects Overall price savings Browse you; possibilities are high that there is some type of item or piece of equipment that has a steel finishing on it.

If you're interested in discovering more regarding metal coverings and how they can help contribute in the success of your organization, our group atis greater than satisfied to help. We give hands-on help, outstanding turnaround times, and also quality welds that will last!today at to tell us even more regarding your upcoming task! (https://vanguardllc.bravesites.com/#builder).

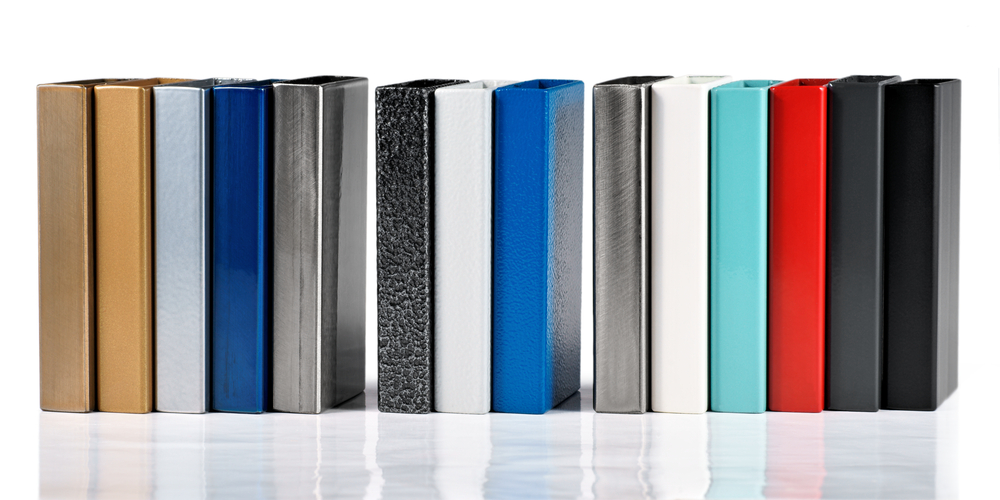

Steel finishings are made use of to stop ferrous metals from rusting and likewise to enhance the appearance of all steels. Each kind of coating achieves a various objective and has its very own appearance. For more details on how metals corrode, inspect out our post regarding galvanic action. While anodizing is most typical with light weight aluminum, resource it can additionally be made use of on various other metals such as titanium and zinc.

When aluminum is subjected to oxygen, a layer of aluminum oxide is formed on the surface of the steel (Fusion Bonded Epoxy near Anderson, SC). Anodizing successfully enhances the thickness of this aluminum oxide layer, that makes it much more immune to corrosion. To further increase the toughness and also corrosion resistance, a clear sealer can be made use of.